User:Milton Beychok/Sandbox: Difference between revisions

imported>Milton Beychok No edit summary |

imported>Milton Beychok mNo edit summary |

||

| Line 25: | Line 25: | ||

*The flare stack, including a flashback prevention section at the upper part of the flare stack. | *The flare stack, including a flashback prevention section at the upper part of the flare stack. | ||

== | ==Environmental impacts of flaring associated gas from oil drilling sites== | ||

{{Image|Nigerian gas flare.jpg|right|250px|Ground-flaring of associated gas from an oil well site in Nigeria.}} | |||

As of the end of 2011, 150 × 10<sup>9</sup> cubic meters (5.3 × 10<sup>12</sup> cubic feet) of associated gas are flared annually. That is equivalent to about 25% of the annual natural gas consumption in the [[United States]] or about 30% of the annual gas consumption in the [[European Union]].<ref name=GGFR>[http://siteresources.worldbank.org/INTGGFR/Resources/GGFR_NewBrochure%28Oct2011%29.pdf Global Gas Flaring Reduction Partnership (GGFR), World Bank], October 2011 Brochure.</ref> | |||

As of 2010, 10 countries accounted for 70% of the flaring, and twenty for 85%. The top ten leading contributors to world gas flaring in 2010, were (in declining order): [[Russia]] (26%), [[Nigeria]] (11%), [[Iran]] (8%), [[Iraq]] (7%), [[Algeria]] (4%), [[Angola]] (3%), [[Kazakhstan]] (3%), [[Libya]] (3%), [[Saudi Arabia]] (3%) and [[Venezuela]] (2%).<ref>[http://web.worldbank.org/WBSITE/EXTERNAL/TOPICS/EXTOGMC/EXTGGFR/0,,contentMDK:22137498~pagePK:64168445~piPK:64168309~theSitePK:578069,00.html Estimated Flared Volumes from Satellite Data, 2006-2010]. From the website of the World Bank.</ref> | |||

That amount of flaring and burning of associated gas from oil drilling sites is a significant source of [[carbon dioxide]] (CO<sub>2</sub>) emissions. Some 400 × 10<sup>6</sup> tons of carbon dioxide are emitted annually in this way and it amounts to about 1.2% of the worldwide emissions of carbon dioxide. That may seem to be insignificant, but in perspective it is more than half of the ''Certified Emissions Reductions'' (a type of carbon credits) that have been issued under the rules and mechanisms of the Kyoto Protocol as of June 2011.<ref name=GGFR/><ref>[http://web.worldbank.org/WBSITE/EXTERNAL/NEWS/0,,contentMDK:21032487~menuPK:34480~pagePK:64257043~piPK:437376~theSitePK:4607,00.html Global Gas Flaring Reduction]. From the website of the World Bank.</ref> | |||

Satellite data on global gas flaring show that the current efforts to reduce gas flaring are paying off. From 2005 to 2010, the global estimate for gas flaring decreased by about 20%. The most significant reductions in terms of volume were made in Russia and Nigeria.<ref name=GGFR/><ref>[http://www.ngdc.noaa.gov/dmsp/interest/flare_docs/NGDC_annual_report_20110209.pdf Estimation of Gas Flaring Volumes Using NASA MODIS Fire Detection Products]. NOAA's National Geophysical Data Center (NGDC) annual report, February 2011.</ref> | |||

==See also== | ==See also== | ||

Revision as of 13:27, 2 June 2012

A gas flare, alternatively known as a flare stack, is a combustion device (see the adjacent photo) used in industrial plants such as petroleum refineries, chemical plants, natural gas processing plants as well as at oil or gas production sites having oil wells, gas wells, offshore oil and gas rigs and landfills.

In industrial plants, flare stacks are primarily used for burning off flammable gas released by pressure relief valves during unplanned over-pressuring of plant equipment.[1][2][3][4][5] During plant or partial plant startups and shutdowns, flare stacks are also often used for the planned combustion of gases over relatively short periods.

However, a great deal of gas flaring at many oil and gas production sites has nothing to do with protection against the dangers of over-pressuring industrial plant equipment. When petroleum crude oil is extracted and produced from onshore or offshore oil wells, raw natural gas associated with the oil is produced to the surface as well. In areas of the world lacking pipelines and other gas transportation infrastructure, vast amounts of such associated gas are commonly flared as waste or unusable gas. The flaring of associated gas may occur at the top of a vertical flare stack (as in the adjacent photo) or it may occur in a ground-level flare in an earthen pit. Such flaring constitutes a hazard to human health and also significantly contributes to the worldwide anthropogenic emissions of carbon dioxide (CO2).

Overall flare system in industrial plants

Whenever industrial plant equipment items are over-pressured, the pressure relief valves provided as essential safety devices on the equipment automatically release gases and sometimes liquids as well. Those pressure relief valves are required by industrial design codes and standards as well as by law.

The released gases and liquids are routed through large piping systems called flare headers to a vertical elevated flare. The released gases are burned as they exit the flare stacks. The size and brightness of the resulting flame depends upon the flammable material's flow rate in terms of joules per hour (or btu per hour).[4]

Most industrial plant flares have a vapor-liquid separator (also known as a knockout drum) upstream of the flare to remove any large amounts of liquid that may accompany the relieved gases.

Steam is very often injected into the flame to reduce the formation of black smoke. In order to keep the flare system functional, a small amount of gas is continuously burned, like a pilot light, so that the system is always ready for its primary purpose as an over-pressure safety system.

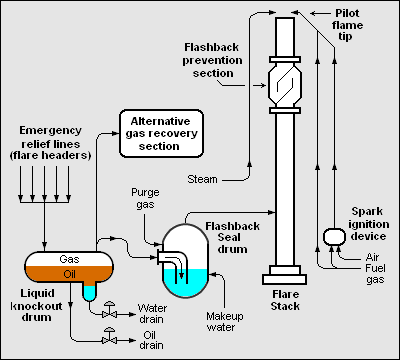

The adjacent flow diagram depicts the typical components of an overall industrial flare stack system:[1][2][3]

- A knockout drum to remove any oil and/or water from the relieved gases.

- A water seal drum to prevent any flashback of the flame from the the top of the flare stack.

- As alternative gas recovery system for use during partial plant startups and/or shutdowns as well as other times when required. The recovered gas is routed into the fuel gas system of the overall industrial plant.

- A steam injection system to provide an external momentum force used for efficient mixing of air with the relieved gas, which promotes smokeless burning.

- A pilot flame (with its ignition system) that burns all the time so that it is available to ignite relieved gases whenever needed.[6]

- The flare stack, including a flashback prevention section at the upper part of the flare stack.

Environmental impacts of flaring associated gas from oil drilling sites

As of the end of 2011, 150 × 109 cubic meters (5.3 × 1012 cubic feet) of associated gas are flared annually. That is equivalent to about 25% of the annual natural gas consumption in the United States or about 30% of the annual gas consumption in the European Union.[7]

As of 2010, 10 countries accounted for 70% of the flaring, and twenty for 85%. The top ten leading contributors to world gas flaring in 2010, were (in declining order): Russia (26%), Nigeria (11%), Iran (8%), Iraq (7%), Algeria (4%), Angola (3%), Kazakhstan (3%), Libya (3%), Saudi Arabia (3%) and Venezuela (2%).[8]

That amount of flaring and burning of associated gas from oil drilling sites is a significant source of carbon dioxide (CO2) emissions. Some 400 × 106 tons of carbon dioxide are emitted annually in this way and it amounts to about 1.2% of the worldwide emissions of carbon dioxide. That may seem to be insignificant, but in perspective it is more than half of the Certified Emissions Reductions (a type of carbon credits) that have been issued under the rules and mechanisms of the Kyoto Protocol as of June 2011.[7][9]

Satellite data on global gas flaring show that the current efforts to reduce gas flaring are paying off. From 2005 to 2010, the global estimate for gas flaring decreased by about 20%. The most significant reductions in terms of volume were made in Russia and Nigeria.[7][10]

See also

- Environmental issues in the Niger Delta (The Delta is the greatest gas flaring site on Earth.)

- Flue-gas stack

- Relief valve

References

- ↑ 1.0 1.1 EPA/452/B-02-001, Section 3.0: VOC Controls, Section 3.2: VOC Destruction Controls, Chapter 1: Flares. (A U.S. Environmental Protection Agency report, dated September 2000.)

- ↑ 2.0 2.1 A. Kayode Coker (2007). Ludwig's Applied Process Design for Chemical And Petrochemical Plants, Volume 1, 4th ed. Gulf Professional Publishing, pp. 732-737. ISBN 0-7506-7766-X.

- ↑ 3.0 3.1 Sam Mannan (Editor) (2005). Lee's Loss Prevention in the Process Industries: Hazard Identification, Assessment and Control, Volume 1, 3rd ed. Elsevier Butterworth-Heinemann, pp. 12/67-12/71. ISBN 0-7506-7857-1.

- ↑ 4.0 4.1 Milton R. Beychok (2005). Fundamentals of Stack Gas Dispersion, Fourth ed. self-published. ISBN 0-9644588-0-2. (See Chapter 11, Flare Stack Plume Rise).

- ↑ A Proposed Comprehensive Model for Elevated Flare Flames and Plumes, David Shore, Flaregas Corporation, AIChE 40th Loss Prevention Symposium, April 2006.

- ↑ Product Overview Ignition Systems, Excellent source of information about flare stack pilot flames and their ignition systems.

- ↑ 7.0 7.1 7.2 Global Gas Flaring Reduction Partnership (GGFR), World Bank, October 2011 Brochure.

- ↑ Estimated Flared Volumes from Satellite Data, 2006-2010. From the website of the World Bank.

- ↑ Global Gas Flaring Reduction. From the website of the World Bank.

- ↑ Estimation of Gas Flaring Volumes Using NASA MODIS Fire Detection Products. NOAA's National Geophysical Data Center (NGDC) annual report, February 2011.